Carry Bag Machine – Advanced Solutions for Sustainable Bag Production

A carry bag machine, also known as a bag making machine or a bag manufacturing machine, is a piece of equipment used for the automated production of various types of bags, such as shopping bags, tote bags, garbage bags, and more. These machines play a crucial role in meeting the demand for bags in retail, packaging, and other industries. They enable efficient and consistent production of bags in different sizes, shapes, and materials.

Here's a more detailed overview of the components and operation of a carry bag machine.

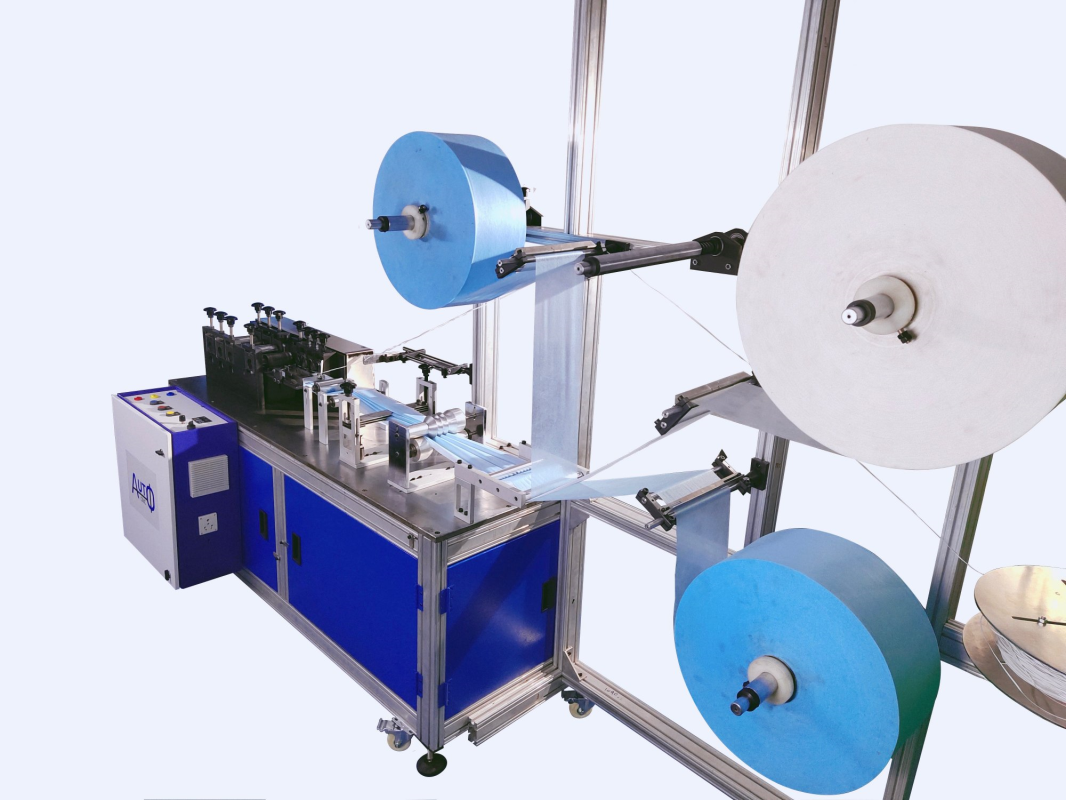

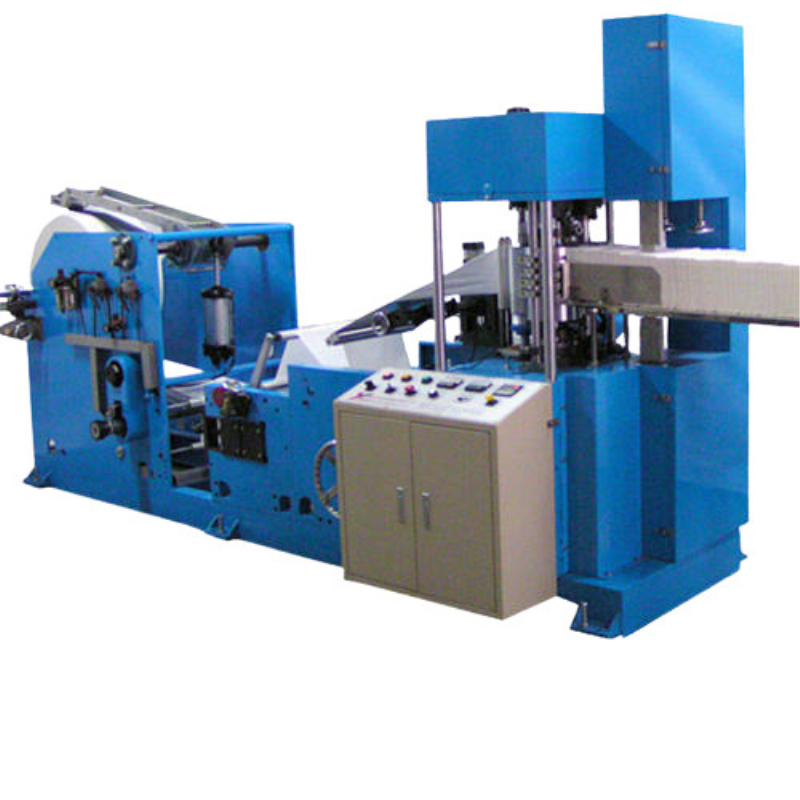

Components of a Carry Bag Machine

- Raw Material Roll Stand: This is where the roll of raw material, typically plastic film or other flexible materials, is loaded. Different types of plastics, including LDPE (low-density polyethylene), HDPE (high-density polyethylene), and others, can be used based on the type of bags being produced.

- Printing Unit (Optional) : Some bag making machines come with a printing unit that allows for designs, logos, or branding to be printed directly onto the bags during the production process.

- Material Cutting Unit : The machine cuts the raw material into sheets of the required size for bag production.

- Bag Forming Unit : This unit takes the cut sheets of material and folds, seals, and welds the edges to form the bag's structure. Heat and pressure are often applied to ensure proper bonding.

- Handles and Features (Optional) : Depending on the type of bags being produced, the machine might incorporate mechanisms to add handles, gussets, or other features to the bags.

- Quality Control and Inspection : Some bag making machines include sensors and systems to detect defects or irregularities in the bags, ensuring that only high-quality bags are produced.

- Collection and Stacking Unit : The finished bags are collected, stacked, and bundled for further packaging and distribution.

Operation

- Raw Material Loading : The roll of raw material is loaded onto the machine's roll stand.

- Printing (Optional) : If the machine is equipped with a printing unit, designs or branding can be added to the bags.

- Material Cutting : The machine cuts the raw material roll into sheets of the desired size.

- Bag Forming : The bag forming unit folds, seals, and welds the edges of the material to create the bag structure. Heat and pressure are applied to ensure proper bonding.

- Handle and Features Addition (Optional) : Handles, gussets, or other features can be added to the bags during this stage if required.

- Quality Control : Sensors and systems inspect the bags for defects and irregularities. Defective bags are often rejected automatically.

- Collection : The finished bags are collected, stacked, and bundled for packaging and distribution.

Key Considerations

- Bag Type and Size : Different bag making machines are designed to produce specific types and sizes of bags.

- Printing and Customization : Some machines allow for printing and customization of bag designs and branding.

- Material Type : The type of plastic material used affects the bag's durability, appearance, and environmental impact.

- Automation : Higher levels of automation can improve production efficiency and reduce manual intervention.

- Maintenance and Training : Proper maintenance and operator training are essential for smooth operation and longevity.

- Sustainability : There's an increasing emphasis on producing eco-friendly bags using recyclable or biodegradable materials.

Carry bag machines are integral to the packaging industry, providing a reliable and efficient way to produce bags for various purposes. As environmental concerns grow, there's a growing focus on producing bags that are sustainable and align with eco-friendly practices.