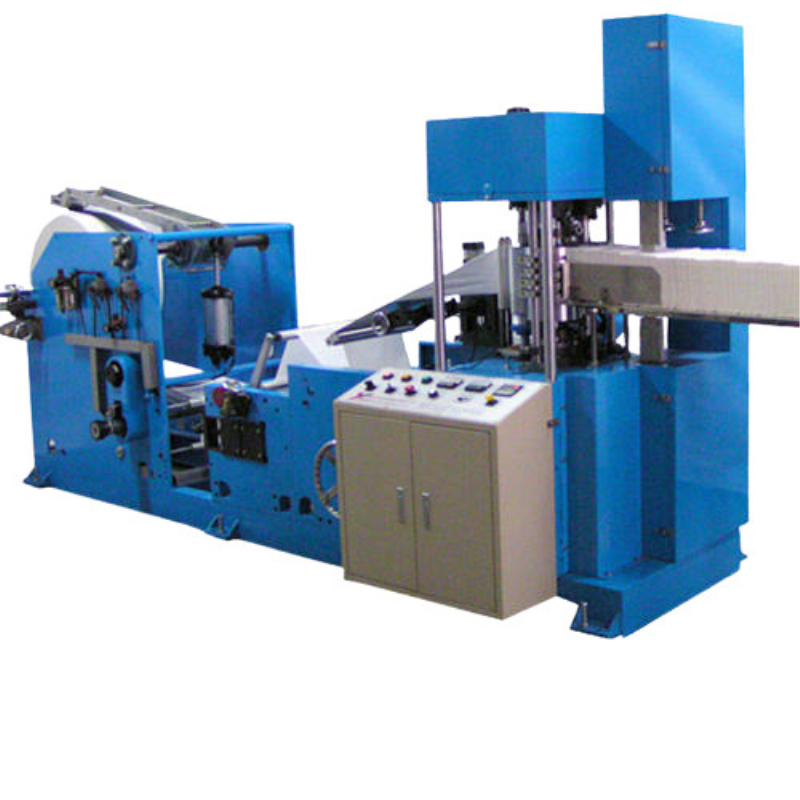

Tissue Paper Making Machine – Efficient Solutions for Premium Tissue Production

A tissue paper making machine is a specialized piece of equipment used for the automated production of tissue paper products. Tissue paper machines play a vital role in the paper manufacturing industry by enabling the efficient and consistent production of various types of tissue papers, such as toilet paper, facial tissues, paper towels, and napkins.

Here's a more detailed overview of the components and operation of a tissue paper making machine.

Components of a Tissue Paper Making Machine

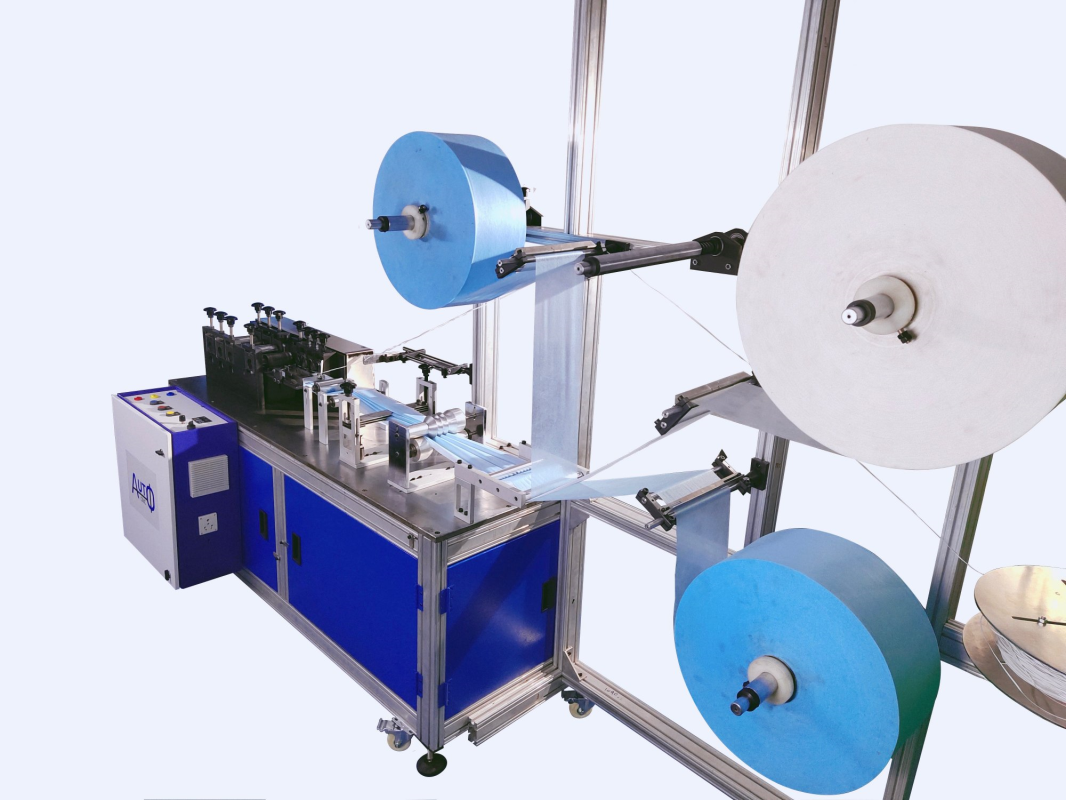

- Unwinding System: The machine takes in jumbo rolls of paper, which are large rolls of paper that serve as the raw material for tissue production.

- Embossing Unit (Optional): Some machines include an embossing unit that adds texture to the tissue paper, enhancing its softness and appearance.

- Printing Unit (Optional): For tissue paper products with branding or designs, a printing unit can be integrated to add patterns or logos.

- Cutting and Slitting Unit: The machine cuts the jumbo rolls into smaller rolls or sheets of tissue paper of the desired size.

- Folding and Stacking Unit: Tissue paper can be folded and stacked into the final product format, such as toilet rolls or facial tissue boxes.

- Packaging Unit: The finished tissue paper products are packaged for distribution, often with protective materials to prevent damage.

Operation

- Unwinding: The jumbo rolls of paper are loaded onto the machine's unwinding system.

- Embossing (Optional): If required, the machine adds texture to the tissue paper through embossing.

- Printing (Optional): If branding or designs are needed, a printing unit can apply patterns or logos.

- Cutting and Slitting: The machine cuts the jumbo rolls into smaller rolls or sheets of tissue paper.

- Folding and Stacking: The tissue paper is folded and stacked into the final product format.

- Packaging: The finished tissue paper products are packaged for distribution.

Key Considerations

- Tissue Paper Type: Different machines are designed for producing various types of tissue papers, such as toilet paper, facial tissues, and paper towels.

- Embossing Options: Some machines offer embossing options to enhance tissue paper softness and appearance.

- Printing Features: Machines with printing units allow for branding and customization.

- Quality Control: Ensuring consistent quality is crucial for producing reliable and comfortable tissue paper products.

- Automation: Higher levels of automation improve production efficiency and reduce manual intervention.

- Maintenance and Training: Proper maintenance and operator training are important for smooth operation and machine longevity.

Tissue paper making machines are essential in providing everyday consumer products used in homes, workplaces, and public spaces. They contribute to the hygiene and convenience of people's daily lives while maintaining high standards of quality and comfort. The choice of machine depends on factors such as the type of tissue paper product, production volume, and quality requirements.