Sanitary Pad Machine – Innovative Solutions for Hygienic Product Manufacturing

A sanitary pad machine, also known as a sanitary napkin machine or a feminine hygiene product machine, is a specialized piece of equipment used for the automated production of sanitary pads, which are absorbent materials worn by individuals during their menstrual periods for hygiene and comfort. These machines play a vital role in addressing menstrual hygiene needs and promoting women's health and well-being.

Here's a more detailed overview of the components and operation of a sanitary pad machine.

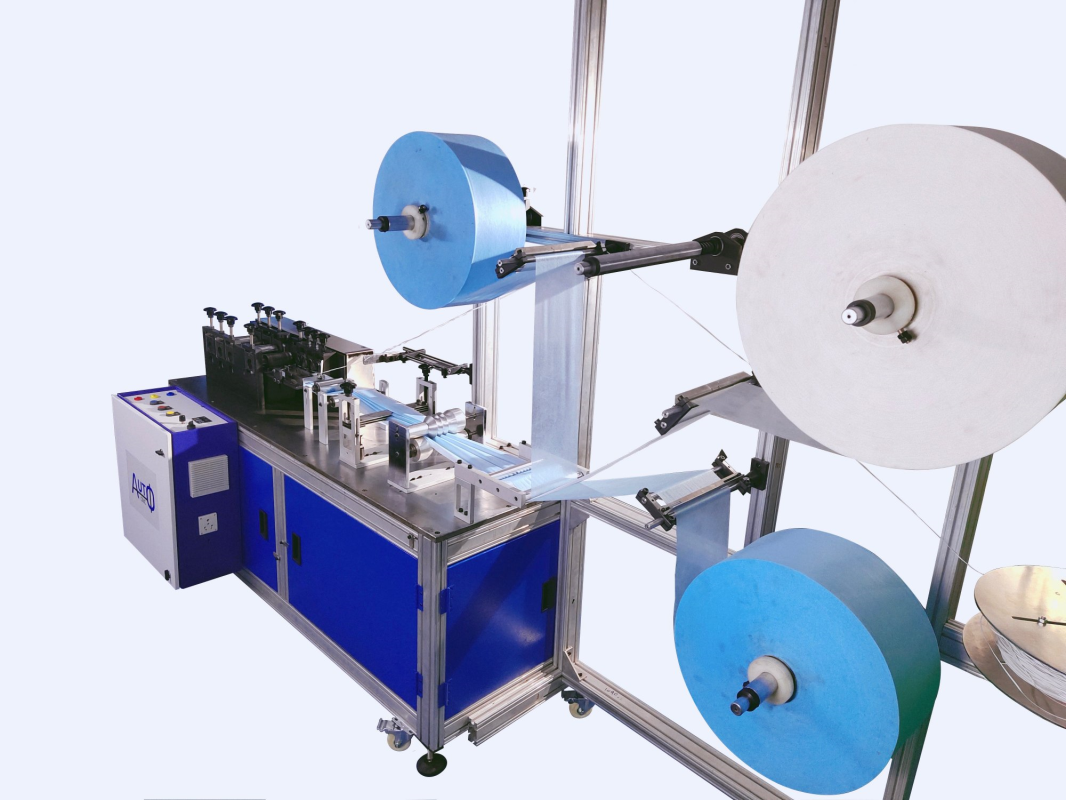

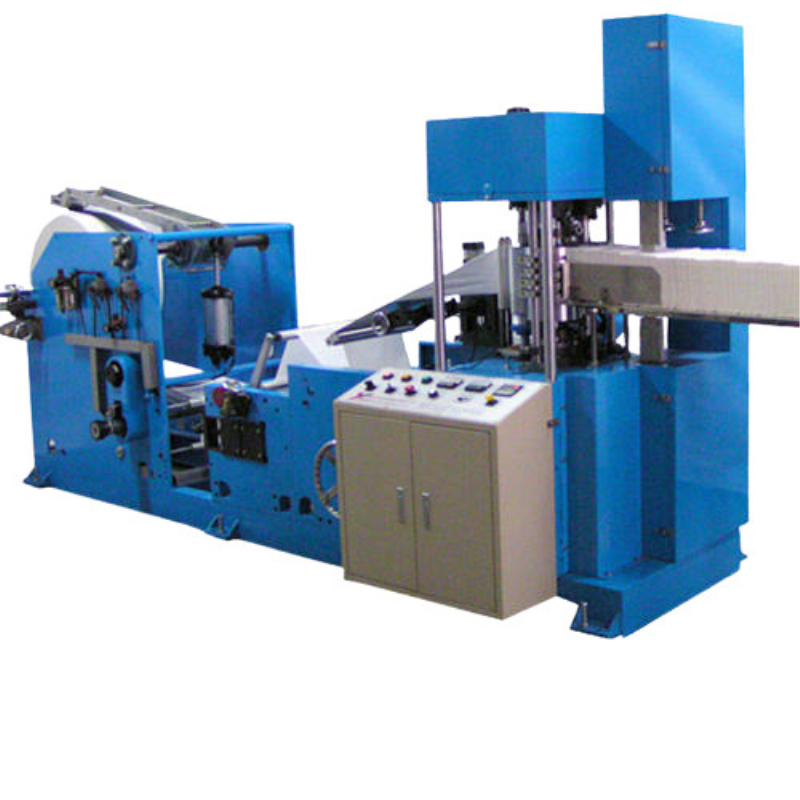

Components of a Sanitary Pad Machine

- Raw Material Feed: The machine takes in the raw materials necessary for making sanitary pads, including absorbent core materials, top sheets, back sheets, and adhesives.

- Absorbent Core Formation: The absorbent core is a critical component of the sanitary pad. The machine forms the absorbent core using a combination of cellulose-based materials that can quickly absorb and lock away menstrual fluid.

- Top Sheet and Back Sheet Application: The top sheet is the layer that comes into direct contact with the body, while the back sheet provides a waterproof barrier. The machine applies these sheets to the absorbent core.

- Cutting and Shaping: The machine cuts and shapes the assembled layers into individual sanitary pad units. The pads are often designed to have wings or flaps that fold over underwear to provide additional leakage protection.

- Fold and Pack: The finished sanitary pads are folded and packaged into individual units or larger packs for distribution and use.

- Quality Control: Some machines incorporate sensors and systems to inspect the quality of the sanitary pads, ensuring they meet the required standards.

Operation

- Raw Material Loading: The raw materials, including absorbent core materials, top sheets, and back sheets, are loaded into the machine.

- Absorbent Core Formation: The machine forms the absorbent core using a combination of materials with high absorbency.

- Top Sheet and Back Sheet Application: The top sheet and back sheet are applied to the absorbent core, creating the basic structure of the sanitary pad.

- Cutting and Shaping: The machine cuts and shapes the assembled layers into individual sanitary pad units, often with wings for better fit and protection.

- Fold and Pack: The finished sanitary pads are folded and packaged for distribution and use.

- Quality Control: Sensors and systems inspect the sanitary pads to ensure they meet quality standards before packaging.

Key Considerations

- Absorbency and Comfort: The design and materials used impact the pad's absorbency, comfort, and overall effectiveness.

- Size and Shape: Different machines can produce sanitary pads of various sizes and shapes to cater to user preferences.

- Packaging Options: Sanitary pads can be packaged individually or in larger packs, depending on the intended distribution.

- Customization: Some machines allow for customization of pad design, including patterns, colors, and branding.

- Automation: Higher levels of automation can improve production efficiency and reduce manual intervention.

- Maintenance and Training: Proper maintenance and operator training are important for smooth operation and machine longevity.

- Health and Safety Standards: Sanitary pad production must adhere to strict health and safety standards to ensure product quality and user safety.

Sanitary pad machines are crucial for providing accessible and affordable menstrual hygiene solutions for individuals around the world. These machines contribute to promoting women's health and addressing menstrual hygiene challenges. As with other industries, there's also a growing interest in producing eco-friendly and sustainable sanitary pads to reduce environmental impact