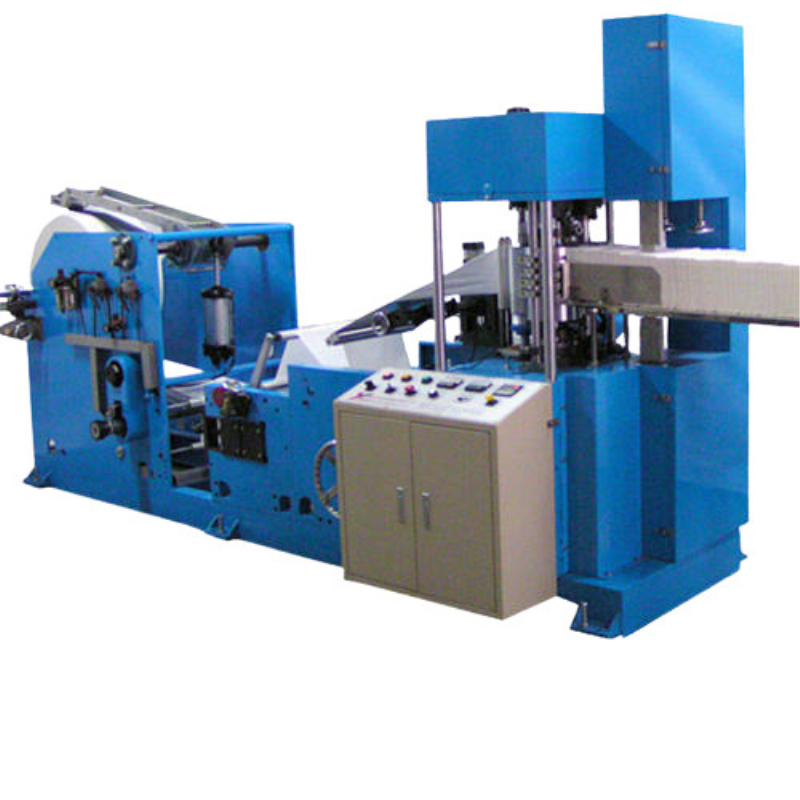

Paper Cup Machine – Efficient Solutions for Sustainable Cup Production

A paper cup machine is a mechanical device specifically designed for the automated production of paper cups. These machines are used to manufacture a wide range of paper cups that are commonly used for serving hot and cold beverages such as coffee, tea, soft drinks, and more. Paper cup machines play a crucial role in meeting the demand for disposable cups in various food and beverage establishments, events, and other settings.

Here's a more detailed overview of the components and operation of a paper cup machine.

Components of a Paper Cup Machine

- Paper Reel Stand: This is where the paper roll is loaded. The paper used for making cups is typically a duplex board coated with a layer of polyethylene to make it waterproof.

- Printing Unit (Optional): Some paper cup machines come equipped with a printing unit that allows for customized branding, logos, or designs to be printed on the paper before cup formation.

- Die-Cutting Unit: The die-cutting unit shapes the paper into cup blanks by cutting the paper into cup-shaped pieces and forming flaps that will be used to seal the cup.

- Cup Forming Unit: The cup forming unit takes the cut cup blanks and folds, seals, and bonds the edges to form the cylindrical shape of the cup. Heat and pressure are applied to melt the polyethylene coating and securely seal the cup walls.

- Bottom Insertion Unit: This part of the machine cuts out a circular piece of paper and inserts it into the bottom of the cup, sealing it in place.

- Quality Control System: Modern paper cup machines often incorporate sensors and quality control mechanisms to identify and reject defective cups, ensuring that only cups that meet the required standards are produced.

- Collection and Stacking Unit: The finished cups are collected, stacked, and bundled for further packaging and distribution.

Operation

- Paper Loading: The paper roll is loaded onto the machine's reel stand.

- Printing (Optional): If the machine has a printing unit, custom designs or branding can be added to the paper.

- Die-Cutting: The machine cuts the paper into cup-shaped blanks, forming the flaps that will be folded and sealed to create the cup structure.

- Cup Forming: The machine uses heat and pressure to fold, seal, and bond the cup walls. This process creates the cylindrical shape of the cup.

- Bottom Insertion: The machine cuts and inserts the circular bottom of the cup, securely sealing it in place.

- Quality Control: Sensors and systems ensure that cups are formed correctly and meet quality standards. Defective cups are automatically rejected.

- Collection: The finished cups are stacked, bundled, and collected for packaging and distribution.

Key Considerations

- Capacity and Speed: Different machines offer varying production capacities and speeds to match specific needs.

- Customization: Some machines allow for customization of cup designs and branding.

- Automation: Higher levels of automation can improve efficiency and reduce the need for manual intervention.

- Maintenance and Training: Proper maintenance and operator training are important for smooth operation and longevity.

- Sustainability: There is growing interest in producing environmentally friendly and recyclable paper cups.

As the demand for disposable cups continues to rise, paper cup machines remain a significant part of the food and beverage industry, catering to the need for convenient and hygienic beverage containers.