Paper Plate Machine – Reliable Solutions for Eco-Friendly Plate Production

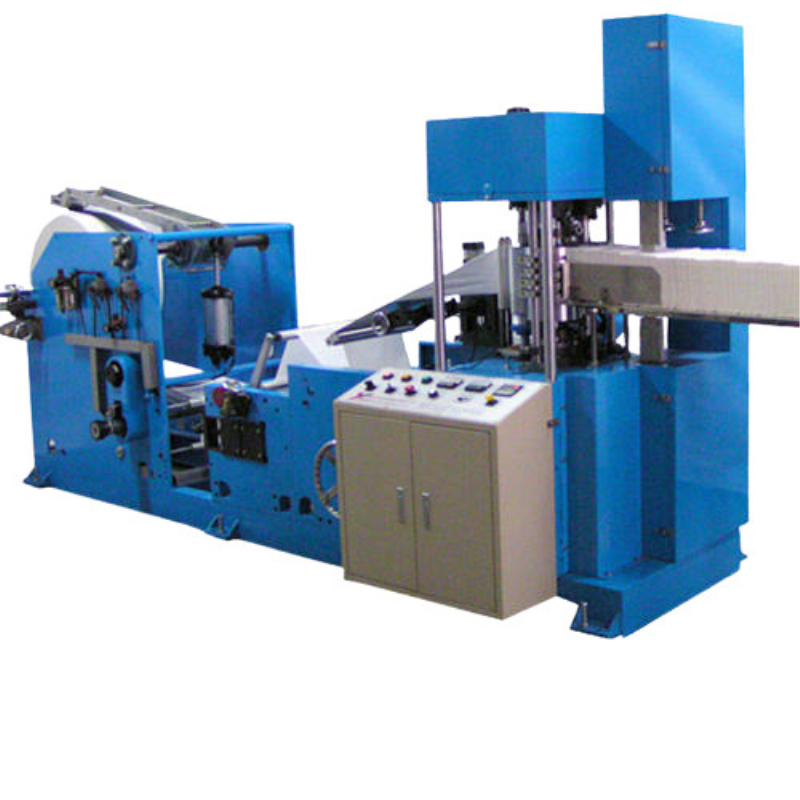

A paper plate machine, also known as a paper plate making machine, is a device used for the automated production of disposable paper plates. These machines are designed to streamline and simplify the manufacturing process, making it more efficient and cost-effective. Paper plates are commonly used for serving food at various events, parties, picnics, and gatherings, and their disposable nature makes them convenient for both hosts and guests.

Here's how a typical paper plate machine works:

- Raw Material Feeding: The machine takes in raw materials, which usually include paper pulp or paper sheets. The paper pulp can be made from wood pulp, bamboo, or other fibrous materials. The sheets are often pre-treated to enhance their strength and durability.

- Molding: The paper pulp or sheets are then fed into the machine's molding section. This is where the pulp is shaped into the desired plate form using molds that define the shape and size of the plates.

- Drying and Pressing: After molding, the plates might undergo a drying and pressing process. This can involve using heat and pressure to remove excess moisture from the plates and give them their final shape and stiffness.

- Trimming and Cutting: Once the plates are dry and stiff, they are trimmed and cut to remove any excess material and ensure uniform size and shape.

- Stacking and Packaging: The finished paper plates are then stacked and packaged for distribution. Some machines might have additional features that automate the stacking and packaging processes.

Modern paper plate machines can be semi-automatic or fully automatic, depending on their complexity and the level of human intervention required. Fully automatic machines can handle the entire process from raw material feeding to packaging without much manual intervention, resulting in higher production rates. .

When choosing a paper plate machine, factors like production capacity, automation level, plate size, and quality of the produced plates should be considered. These machines come in various sizes and configurations to accommodate different needs and production volumes. .

It's worth noting that my knowledge is based on information available up until September 2021, and there might have been advancements or changes in paper plate machine technology since then. If you're interested in the most up-to-date information, I recommend checking with manufacturers or industry sources. .